unipower

unipower  June 13,2025

June 13,2025

There are two types of automotive LED headlight drivers: integrated driver and external driver.

Integrated Driver: The integrated driver is the integrated design of the driver. Like the integrated graphics

card of the computer motherboard, the led headlights directly integrate the driver board into the lamp body,

and there is no need for an external driver like the externally driven led headlights. The led headlights are

directly connected to the wires and plugs, and the driver cannot be seen, and it is integrated in the lamp body.

Plug-in Driver: The plug-in driver is a split drive design. The driver board is not integrated in the lamp

body, but is an independent plug-in type. The led headlights are first connected to the driver, and then the

driver is connected to the plug.

|

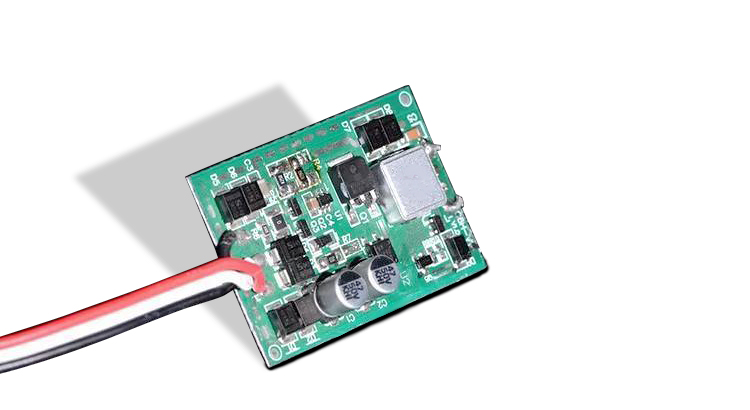

(Automotive LED headlight PCB driver board) |

| PCB, the carrier of electrical connection of electronic components, is made by electronic printing, also known as "printed" circuit board. "PCB driver board" is the general term for the PCB circuit board and the various electronic components it carries. |

A. The integrated driver does not require additional installation space, and the overall

installation rate is higher

The integrated driver is integrated in the lamp body, no external driver is needed, which saves installation

space, and can be installed in a small lamp cup.

B. The external driver takes up installation space, and some assemblies cannot be installed

The external drive needs to take up the installation space, and it may not be installed in the headlight

assembly with medium or small lamp cups.

A. Integrated drive design is more difficult

The design of the integrated driver board is limited by the internal space position of the sunflower (led

headlight fin radiator). It is necessary to repeatedly test the direction and setting of the electronic circuit, as

well as the layout of diodes, MOS tubes, resistors, inductors and other components. Can't let go of it carelessly.

The integrated driver puts forward high requirements on the design ability and processing technology of

the PCB board, and has also formed a higher threshold.

B. Split drive design is relatively easy

The split driver board has its own space. The spatial layout of diodes, MOS tubes, resistors, inductors and

other components can be relatively loose, and the requirements for electronic circuit design, electronic

component layout and processing technology are not as high as integrated.

Whether it is integrated or external, the current mainstream cooling method is fan cooling. Fan cooling is

an active cooling method, the fan rotates at a high speed, and the air convection takes away the heat.

The integrated drive does not require additional installation space, and the overall assembly rate is higher,

but the design capability and processing technology of the PCB drive board are also higher;

The external driver requires additional installation space, and the headlight assembly with a small installation

space cannot be installed, but the PCB driver board can be equipped with more components, which can

achieve more and more cool functions, such as the "three-color four-mode" function.

For riders, choosing integrated drive LED headlights has the same effect, but the installation saves time, effort and worry!